Precision CNC Machining Services

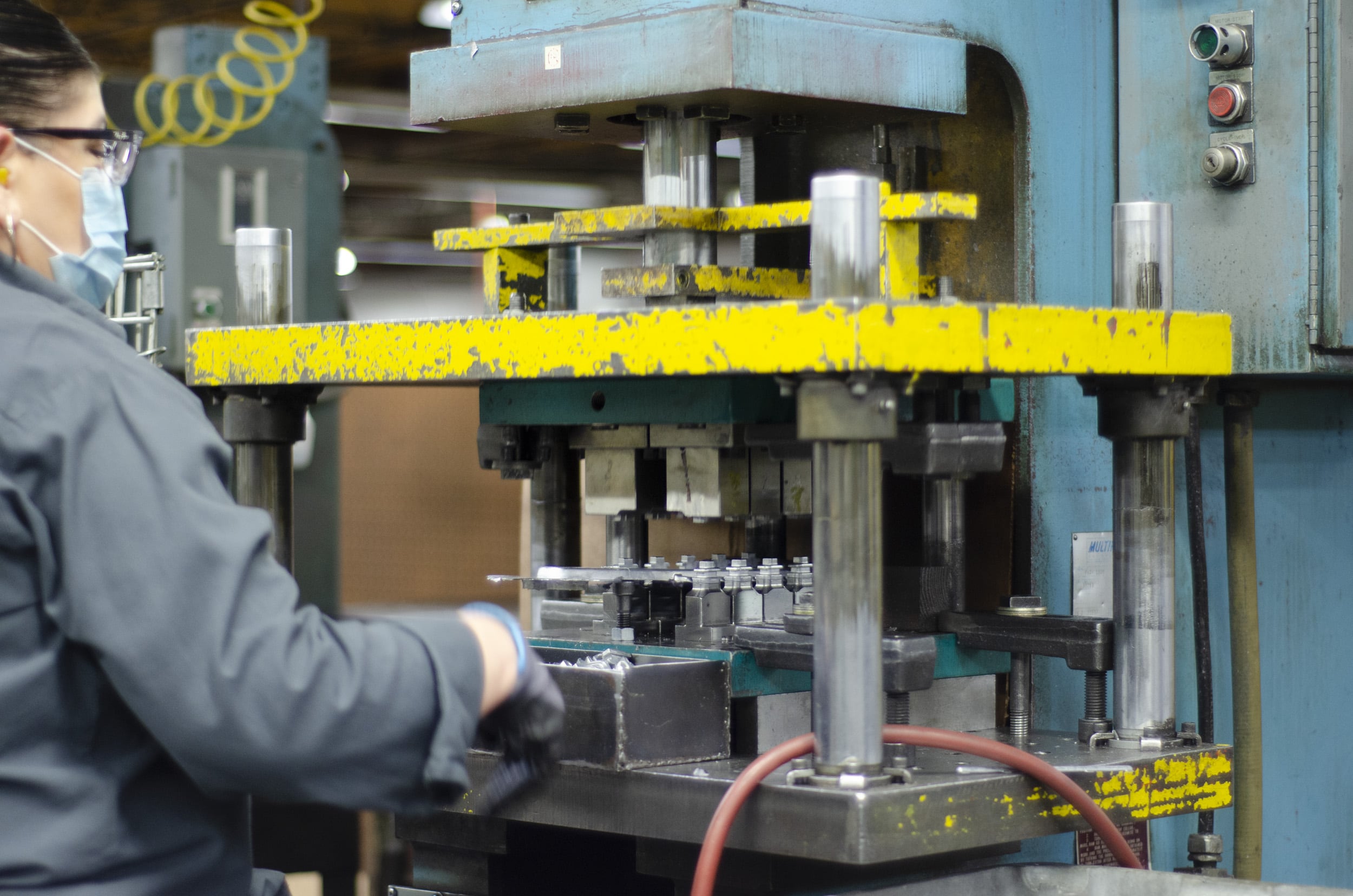

G & M Die Casting offers Computer Numerical Control (CNC) machine shop services to complement our die casting services. Having this secondary option ensures that our customers receive the product that meets their requirements, thus reducing waste. We utilize custom CNC machining for finishing or fine-tuning aluminum die cast parts.

While some die cast parts require only simple finishing processes, such as drilling or metal removal, others need high-precision, post machining to achieve the part’s required tolerance or improve its surface appearance. With several CNC machines, G & M Die Casting performs in-house machining of our die cast parts, making us the convenient single-source solution for all your aluminum die casting needs.

Akin to sculpting a 3-D art project, the CNC machine is programmed to shape parts by cutting away unnecessary metal. CNC machining takes significantly less time than casting; it does not require the production of dies and setup is much quicker. Automating production offers levels of precision and repeatability that die casting alone cannot achieve. The result is consistent, assembly-ready parts.